BUILDING STRUCTURE AND INTERIOR SYSTEMS

Avio Homes is working with the industry’s top energy trendsetters using SIP Panels to disrupt and define the building

landscape. We build structures so energy efficient that you’ll actually enjoy looking at your electric bill.

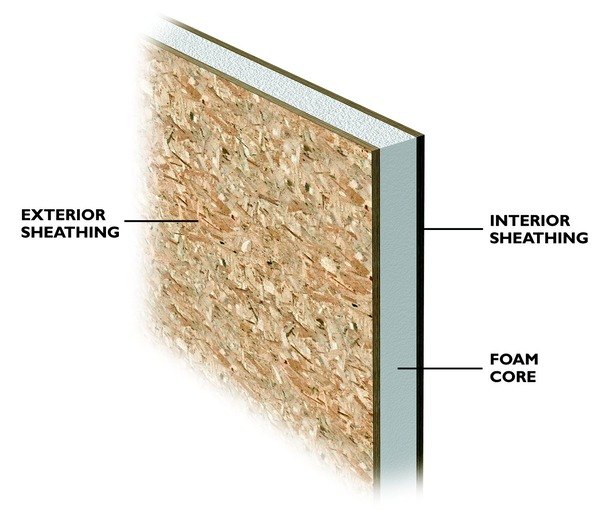

WALLS, FLOORS, ROOF

- Envelope: polystyrene structural insulated panels (SIPS) manufactured in WA

- All joints sealed with SIP-Seal mastic and Vapor Tape

- 60% tighter than WA Energy Code requirements

- Minimal thermal bridging compared to conventional stick-built homes

- Factory production minimizes waste, keeps workers safer, and reduces framing time by ~50%

- Floors: 6” SIPs; R-38 total

- Walls: 4” graphite-infused SIPS; R-21 total

- Roof: 8” SIPS, R-38 total

- Insul-Beam headers

- Insulated wall corners

IS R-VALUE CONSISTENT OVER TIME?

When selecting an insulation product, it is important to recognize that there is an individual R-value of the material,

such as a roll of fiberglass batt or a SIP panel. Then, there is the R-value of a whole wall or roof once the product is

actually installed (effective R-value).

Initial R-Values Of Insulation

Batt insulation overflowMost manufacturers list the individual R-value of their insulation products. This R-value

represents the R-value of that piece at the time of installation under ideal conditions. For instance, if you purchase a

roll of R-19 fiberglass insulation, that number refers to the best possible R-value offered by that roll of insulation.

However, once the batt is installed, the value starts to go down immediately.

Fiberglass insulation works in tandem with air, so any compression of the batt will reduce its effectiveness. The width

of R-19 batt is listed as 61⁄4-inches. It is recommended for use with a 2′′ x 6′′ stud wall. However, 2′′ x 6′′ studs actually

come in a nominal size of about 51⁄2-inches. Since the studs have a width that is 3⁄4” smaller than the batt, the

installation of the drywall compresses the batt insulation in the wall cavity. This reduces the air in the batt, and

subsequently, the R-value.WINDOWS:

What Is U-Factor?

While the R-value of a material measures the thermal resistance, the U-factor (U-value) measures the rate of thermal

transmittance through a material. Thermal transmittance takes heat transfer due to conduction, convection, and

radiation into account. For instance, the energy efficiency of a window is commonly listed by U-value because the

configuration of a window needs to address all three methods of transmission: conduction of energy through

materials such as the glass or casing, convection through any unsealed parts of the window, and radiation (from the

sun) through the glazing applied to the windows.

Rising Popularity Of Accessory Dwelling Units (ADUs).

Imagine building a new smaller home on your property that increase your equity while also allowing you to rent this

space to family or friends. AvioHomes is your perfect solution to addressing income after retirement. and having this

structure paid for in 15 years by your renters.

As cities sprawl and infill redevelopment happens, accessory dwelling units or Detched accessory dwelling units

(DADUs) are becoming quite popular. This is because, in part, they increase the available supply of affordable

housing. Some municipalities now require these units. However, ADUs, also known as laneway houses, granny flats,

in-law units, and carriage houses, are more than a way of planning and managing urban sprawl. They make ideal

structures for multi-generational families to live together while still maintaining private spaces for everyone.

ROOFING SYSTEM

- Composite shingle roof (30 year warranty standard) or optional 26-gauge standing seam steel roof

- 5/4 x 8” cedar fascia, primed on all surfaces for long life

- Multiple colors

- Continuous K-style aluminum gutters with downspouts

- Ice & water shield, 2” drip edge

SUSTAINABILITY

- Optional 4 or 5 star Built Green certification

- Zero VOC paints for healthy indoor air

- High efficiency heating and cooling

- Local materials selected wherever possible: cabinets, flooring, structural panels, etc

SIP CONSTRUCTION

BUILD FASTER, MORE EFFICIENTLY, WITH SIPS

Insulspan’s industry-leading, ready-to-assemble (RTA) building system gives residential and commercial builders a

competitive edge over traditional stick frame construction. Our system facilitates faster framing times, less job site

waste, and a reduced dependency on traditional framing crews.

The Insulspan® SIP system accelerates construction time because SIPs are truer, straighter, and faster to install

than stick framing. This faster assembly means building with SIPs is not as affected by the seasons. In fact, building

with SIPs can reduce the time needed to reach the dry-in phase by up to 50%.

Insulspan’s ready-to-assemble SIPs also eliminate on-site, on-the-fly calculations, and cutting. In turn, the chances

for error and the resulting delays on your project, diminish. Precisely cut in a controlled manufacturing environment,

your Insulspan SIPs meet your exact blueprint specifications. This means the panels arrive at your job site as a

true, ready-to-assemble building system.

Prefabricated Building Method

Prefabricated building methods are in high demand, and Insulspan SIPs are a great prefab building solution. For

example, Insulspan SIPs combine a building’s framing and insulation into one step. Thus, reducing the need for two

subcontractors – framers and insulation installers. Additionally, wire chases for electrical can be cut ahead of time,

during the manufacturing process, at standard heights for outlets and switches as well as wherever they are

specified in the construction drawings.

Finally, with Insulspan’s ready-to-assemble package, the lumber needed during the installation process is pre-cut.

This includes the lumber for the window and door bucks as well as the panel-to-panel connections. The lumber is

pre-installed where possible. All additional materials needed for panel installation is provided, including sealant,

tape, foam, fasteners, and building wrap.

Fast Sip Wall Install SIPs improve a project’s overall efficiency and job site accuracy. When you use Insulspan’s

ready-to-assemble (RTA) package, building can start as soon as the SIPs are delivered, using our detailed, high-quality shop drawings and installation guide.

Building with ready-to-assemble SIPs also reduces your dependence on framing crews. Utilizing smaller crews

decreases your overhead labor costs and limits the time your crew stands around waiting for materials or a

foreman. In fact, using structurally insulated panels reduces framing labor needs by as much as 55% according to a

study conducted by RS Means for BASF.

Additionally, using prefabricated SIPs significantly reduces job site waste. In short, material utilization rates can be

as high as 93% according to a different BASF study. This is because the structural insulated panels are

manufactured off-site and delivered to your job site ready to assemble.

Another benefit is the decrease of job site material walk-offs and theft since SIPs allow you to lock up a building

faster than a stick-built building.

Finally, building with Insulspan SIPs means you receive your delivery when it was scheduled. We leverage our

strong relationships with logistics companies while coordinating with you. This ensures your SIP system package

arrives perfectly timed for the next step in your construction process.

We recognize that the most successful projects are the well-planned ones. It’s why we offer builders and architects

extensive technical resources, including product and technical details as well as construction assembly details. Your

access to online instructional videos, on-site technical advisors, and our hands-on seminars at Insulspan University means we are always available for expert advice and assistance during and after your SIP install.

This ‘disconnect’ keeps the interior of the home well insulated.

Conventional framing with 2×6 walls will only provide you with an R-Factor of 19.

We achieve an R-Factor of 48 with our walls.

Just another Avio Homes innovation that helps create a Green Planet!